Sanofi expanding Fabrazyme plant in MA

Sanofi Genzyme confirmed the capacity increase at the site to Biopharma-Reporter after the news was broken by a local business journal.

“We are expanding our manufacturing production capacity in Framingham, in support of our portfolio and pipeline therapies with a 14,820 square-foot addition to a new building on our campus,” spokesperson Nicolas Kressman said.

Details regarding the size of investment and the hiring of staff were not divulged.

The facility was approved and opened in 2012 in order to support Sanofi’s Fabry disease treatment Fabrazyme (agalsidase beta), freeing up capacity and cutting bottlenecks at Sanofi’s nearby Allston Landing site.

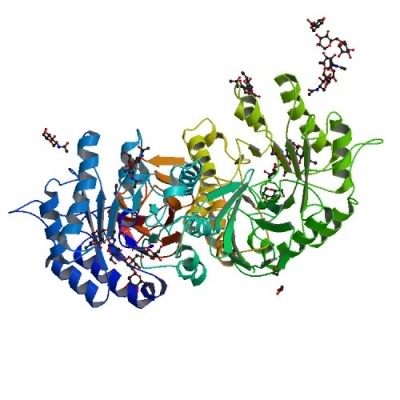

Fabrazyme is an enzyme replacement therapy first approved in 2003 in order to treat the inherited disorder Fabry Disease - a deficiency of the enzyme alpha galactosidase A - and costs approximately $200,000 per year.

Allston Landing was at one time running at production level of 30% of the demand for the drug, leading to severe shortages and a petition by patients to force Genzyme to break the drug’s patent

In 2013, Sanofi said the Framingham site had solved the supply issues, and announced a further $80m investment in a new downstream plant in preparation for anticipated growth in demand for the drug.