Oxford BioMedica could pocket $100m on Novartis CAR-T cell success

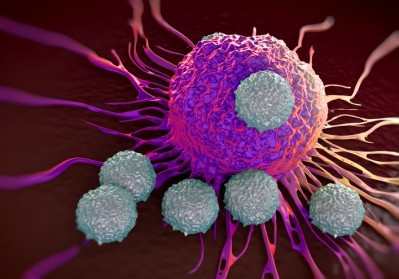

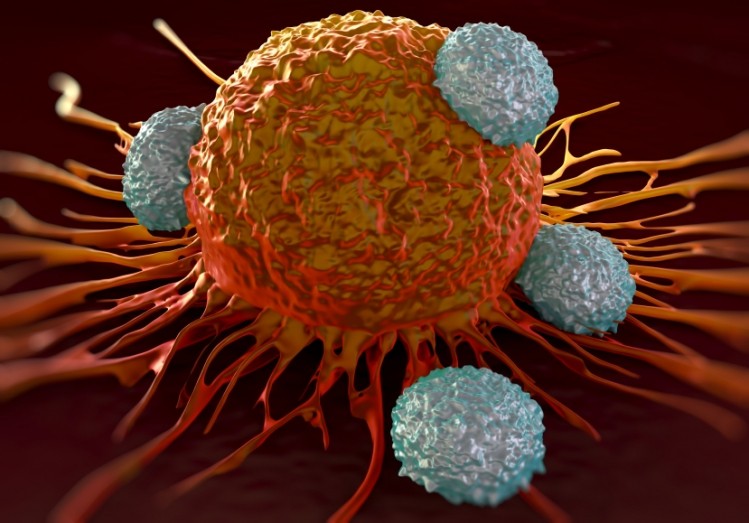

The US approval of the first autologous chimeric antigen receptor (CAR) T cell therapy Kymriah (tisagenlecleucel) has been heralded as a historic moment in cancer treatment, and at a price of $475,000 (€400,000) for a one-time infusion, is set to provide a healthy return on investment for developer Novartis.

But the firm is not the only company set to profit from the success. Oxford BioMedica inked a deal with the Swiss Pharma giant in October 2014 to supply lentiviral vectors expressing CTL019/CART-019 made using its proprietary LentiVector platform, and extended the arrangement in July.

“We are the sole supplier of lentiviral vectors so will be supplying Novartis with this for all CTL019 batches,” CEO John Dawson told Biopharma-Reporter.

“We are already receiving batch revenues and OXB could potentially receive in excess of $100m from Novartis over the next three years. In addition, we will receive royalties under the 2014 agreement once sales commence."

The UK-based company’s share price rose by 21% following the US Food and Drug Administration’s (FDA) approval yesterday.

The firm’s lentiviral-based gene delivery system produces viral vectors used in genetically modifying T-cells extracted from a patient, which – when administered back into the patient – target cancer cells.

According to the firm, the LentiVector platform overcomes the safety and delivery challenges associated with earlier generation of vectors, offering therapeutic payloads of up to 9kb (Kilo-base pairs), permanent modification of dividing and non-dividing cells, and no pre-existing immunity.

The viral vectors are manufactured in GMP suites at its facility in Oxford, UK. “We have three independent clean rooms which operate both cell factories and next generation single-use 200 litre bioreactors,” Dawson told us.

“We have sufficient capacity to fulfil all Novartis’ requirements and so there are no plans to expand at present. Should there be more deals, however, we may look into expanding.”