Patented GE bioreactor bag boasts of 214m CHO cells/mL in perfusion mode

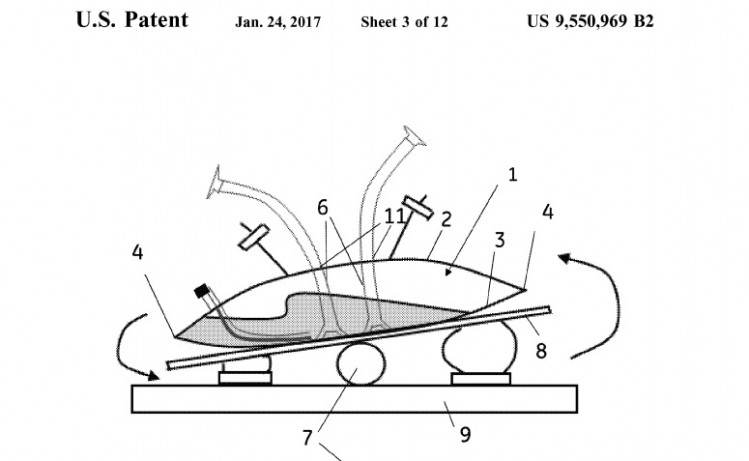

US patent 9550969, entitled ‘Flexible bag for cultivation of cells,’ was granted to GE Healthcare Bio-Sciences last week for inflatable single-use bioreactor bags configured to intensify agitation of the cell suspension.

“Bag designs that would fall under these patent claims were investigated for use with rocking bioreactors run in perfusion mode, with external hollow fiber filters run in tangential flow filtration (TFF) or alternating tangential flow filtration (ATF) mode as cell retention systems,” Eva Lindskog, marketing leader at GE Healthcare Life Sciences told Biopharma-Reporter.com.

Perfusion mode provides a constant environment favourable to the cells by continuous by-product removal and nutrient addition, and with the patented bags research shows what GE believes to be “the highest reported cell density achieved in a single-use bioreactor system to date: 214 million CHO cells/mL” she added.

The research was carried out in collaboration with the Royal Institute of Technology in Stockholm, Sweden, which in a paper published in the Biotechnology Progress journal in 2013 (DOI 10.1002/btpr.1704) states the biomanufacturing industry a cell density is considered “middle-high or high” at 20 to 50 x 106 (20-50 million) cells/mL.

According to Lindskog, a further benefit of the inflatable bag is in mitigating risks associated with using bioreactors with low liquid height, such as a rocking bioreactors compared to stirred tank bioreactor.

“When you work with an ATF as a retention system at low liquid heights, especially as the bioreactor moves as it does in a rocking system, the risk increases for getting air bubbles trapped in the retention system,” she said. “Air bubbles compromise the functionality of the ATF system and this invention mitigates that risk.”

Despite the patent being granted, the functionality is currently not available as a standard bag.

“However, we are actively investigating novel designs, novel single-use films and better functionality of the existing bags in our single-use portfolio,” Lindskog said.