Customisable chromatography resin maker Avitide boosted by Series D funding

Two months on from signing a long-term lease for a former Merck & Co. facility at the Dartmouth Regional Technology Center, New Hampshire, Avitide has secured a round of financing from global investment firm Mithril.

The affinity purification solutions company did not disclose the amount of funding, but CEO Kevin Isett told Biopharma-Reporter “Mithril is a firm that invests with conviction and their involvement comes at a very exciting phase for Avitide.”

He said the proceeds allow Avitide to broaden and grow its product offering, based around the concept of customisable affinity purification resin delivered in three months which aids partners by speeding up development of their biopharmaceuticals.

“Unlike the majority of resin suppliers, Avitide does not offer a catalog of ‘off-the-shelf’ affinity resins,” he told us.

This, he continued, fits with growing demand from drugmakers for conventional improvements to drug purity, potency, and lower cost of manufacturing, and a platform that enables speed to clinic for any molecule.

“Our partners are the driving force for innovation at Avitide: They define the metrics for affinity resin selectivity and performance based on their molecule and biomanufacturing objectives. Avitide then delivers the technology solution in three months.”

Protein B?

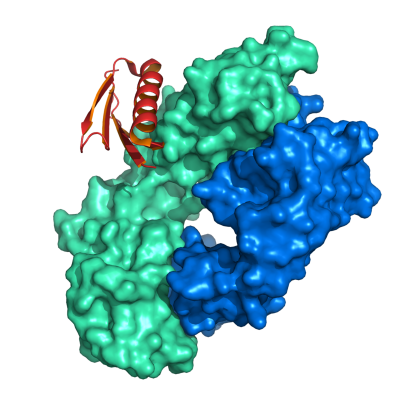

Avitide focuses on developing resins to capture gene therapy vectors, vaccines, bispecific antibodies, and therapeutic proteins. However, Isett said the firm is not focused on the monoclonal antibody resin market which is “well served by the current Protein A resin offerings.”

Protein A is a chromatography resin deemed to be the gold standard in capturing monoclonal antibodies, despite its high cost which can contribute up to 30% of the costs of making a product.

“Protein A has demonstrated the value that a high-performing affinity purification technology can deliver to downstream bioprocessing,” Isett continued, and while it can only be used for mAbs and Fc-bearing molecules, the resin’s strong technical and performance-related lessons can be applied to other biological therapeutic and vaccine molecules.

“To date, the development of affinity resins has been viewed as taking too long to be compatible with downstream development timelines; this is no longer valid,” he said.

“Avitide has developed a disruptive approach that allows bioprocess engineers to rapidly design, discover, and develop affinity resins towards any molecule. In addition to conventional capture applications, molecular features that confer a critical quality attribute can also be implemented, thus enabling quality by design by virtue of the affinity purification step. This is a clear difference from Protein A.”